Segmental Bridge Analytical Capabilities

Our core analytical tool for segmental bridges is SFRAME/S3D© , an advanced version of the SFRAME computer program developed by OPAC Vice President Dr. Mark Ketchum in the 1980's. It provided one basis for the 1989 AASHTO Guide Specifications for Segmental Bridges. OPAC has since upgraded the program for faster operation, cable-stayed and composite capabilities, and better creep models.

Our core analytical tool for segmental bridges is SFRAME/S3D© , an advanced version of the SFRAME computer program developed by OPAC Vice President Dr. Mark Ketchum in the 1980's. It provided one basis for the 1989 AASHTO Guide Specifications for Segmental Bridges. OPAC has since upgraded the program for faster operation, cable-stayed and composite capabilities, and better creep models.

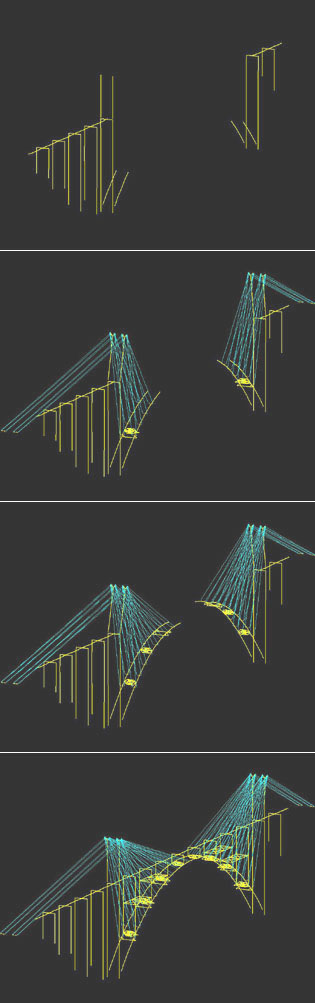

SFRAME/S3D© has been used and validated in construction control, design, research, and forensic applications of all bridge types. Its most recent comprehensive application is in development of erection procedures, stage-by-stage analysis and geometry control for the Hoover Dam Bypass, Colorado River Bridge. It has the following basic capabilities:

3D analysis for arbitrary construction sequence, schedule, and topology. Nonlinear solution using full Newton (tangent stiffness) method for large displacements and element-specific state determination.

Camber, unstressed geometry, and shape-finding analysis using a multi-trial solution for nonlinear structures, fully conformed for structures curved in space.

Dynamic property extraction and export to SAP2000 at any construction stage.

Input specification by reference to an arbitrary curvilinear alignment geometry.

Output to text files and/or spreadsheet files. Spreadsheet post-processor allows generation of meaningful, compact, custom-tailored analysis reports.

Creep analysis considering concrete as an age-hardening viscoelastic material using efficient numerical integration for rapid analysis. Automatic parameter fitting to ACI, CEB/FIP, Bazant, and ad-hoc aging, creep, and shrinkage kernels.

Layered 3D frame elements for composite and staged-construction cross sections. Automated checking of demands against strength and serviceability limit states.

Nonlinear cracking analysis of concrete elements, including the effects of axial load, biaxial moment, age hardening, and creep.

Stay cable elements based on nonlinear true catenary solution, with jacking to force, elongation, or node displacement. Includes stay steel relaxation.

Post tensioning with internal and external, bonded and unbonded tendons. Generation of 3D geometry, initial forces including friction and anchor set.

Contact / uplift elements to model support lift-off at load transfer or decentering.

Traveling formwork / temporary works elements with automated movement and launch.