3D Modeling Capabilities

OPAC has considerable expertise in creating 3D surface models for rapid prototyping and detailing, photorealistic rendering and project visualization, and developing input geometry for structural analysis as well as for preparing 3D integrated shop drawings for conflict checking and resolution.

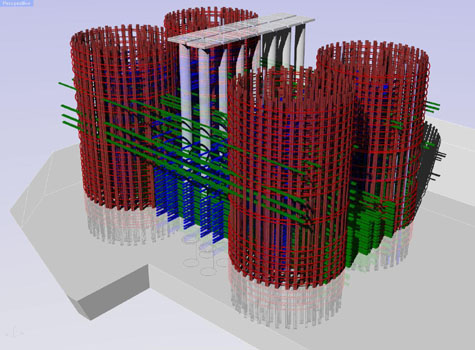

OPAC uses the NURBS-based surface modeler Rhinoceros 3D by McNeel & Associates. Rhino is an extensible program that can be scripted for automation and use with other programs such as Microsoft Excel, SAP2000 or OPAC's proprietary SFRAME/S3D program. A special Rhinoscript (an extension of VBscript) was developed by OPAC to systematically check for intersections between embedded items and report the locations of those conflicts in Microsoft Excel.

Application of our 3D Modeling Capabilities

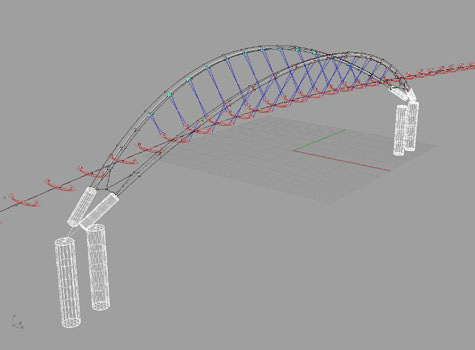

Concept Study of the Floyds Fork Park Bridge in Tennessee - 3D modeling for rapid prototyping and visualization of a 470-foot catenary foot bridge.

Construction Engineering for the Colorado River Bridge, Hoover Dam Bypass - 3D modeling for rapid prototyping and detailing of temporary supports and equipment used to build an 1100 foot span spandrel arch.

Construction Engineering for the Iron Horse Trail Pedestrian Overcrossing, CA - 3D modeling to confirm contract drawing geometry and to develop section properties and member geometry input for an erection analysis.

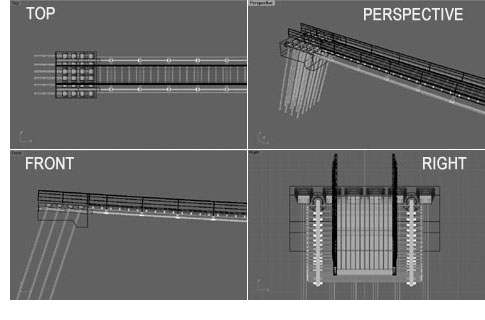

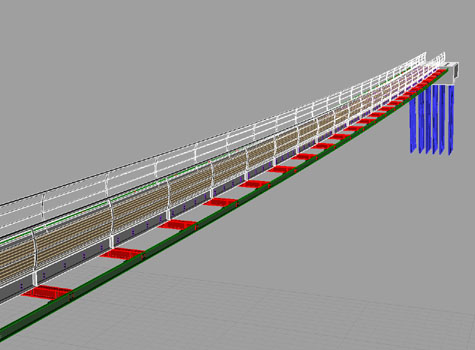

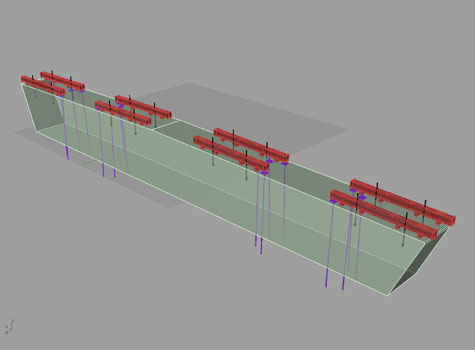

Construction Engineering for the Self-Anchored Suspension Bridge, San Francisco/Oakland - 3D Integrated Shop Drawings Rhino was used to model the W2 cap beam for the purpose of checking and resolving conflicts between numerous embedded items.